Tool & Die Course

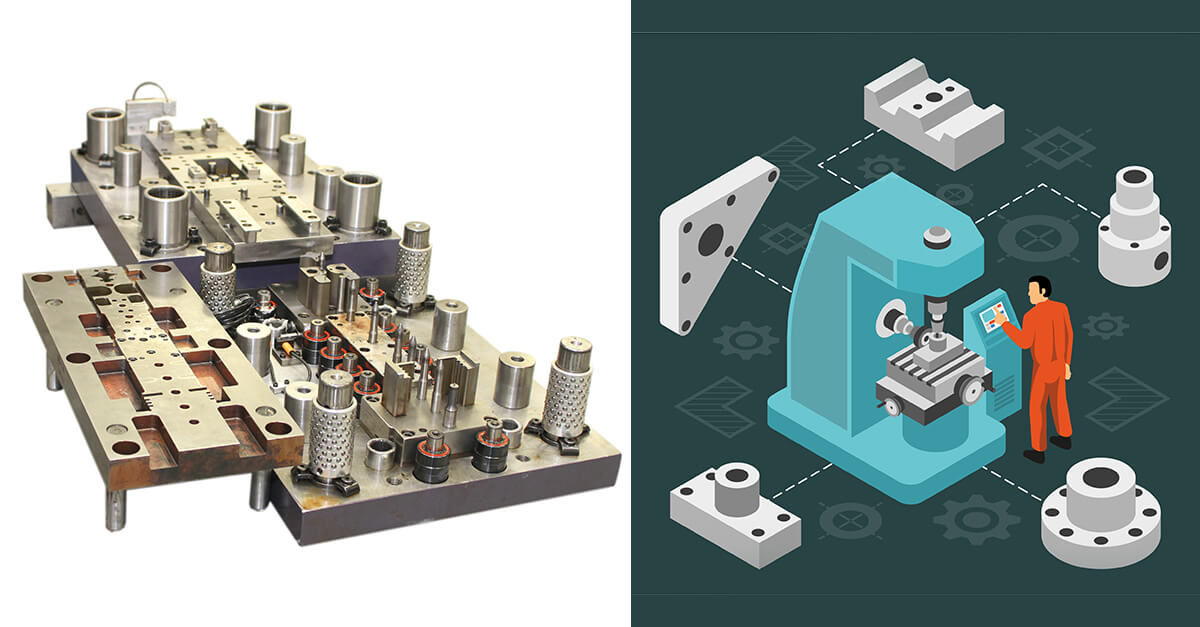

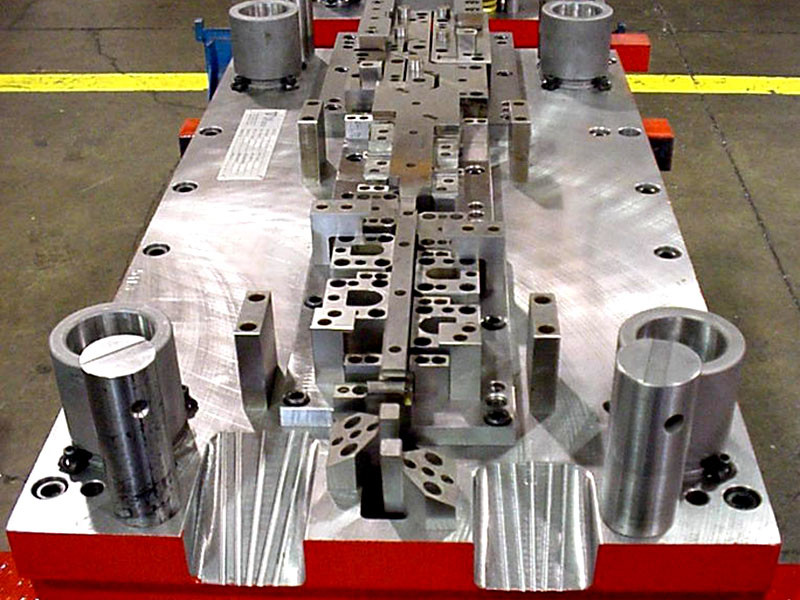

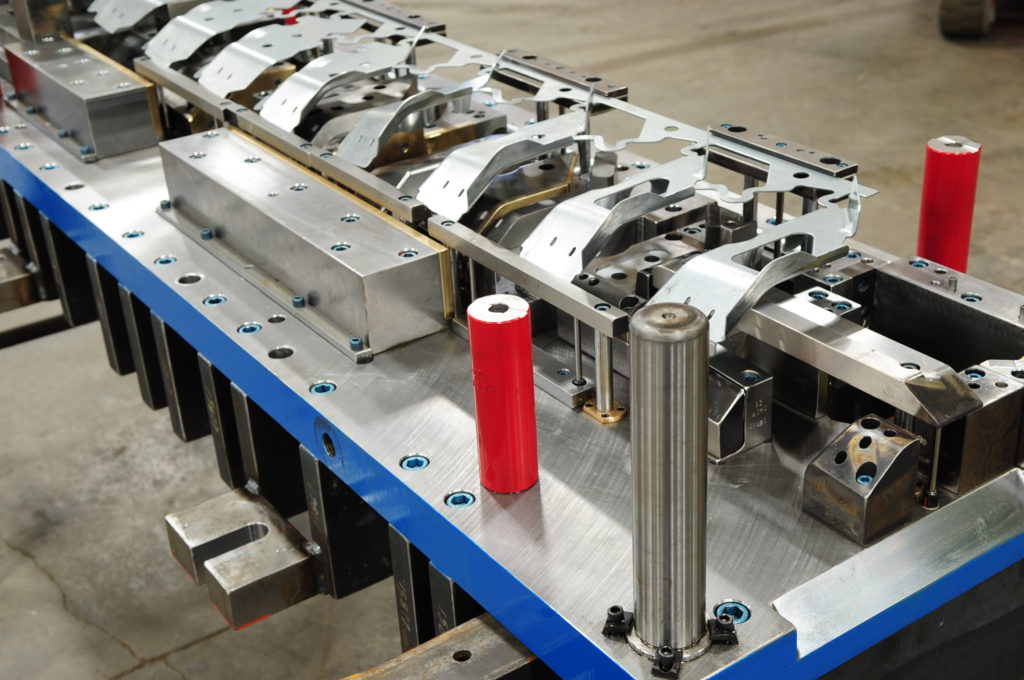

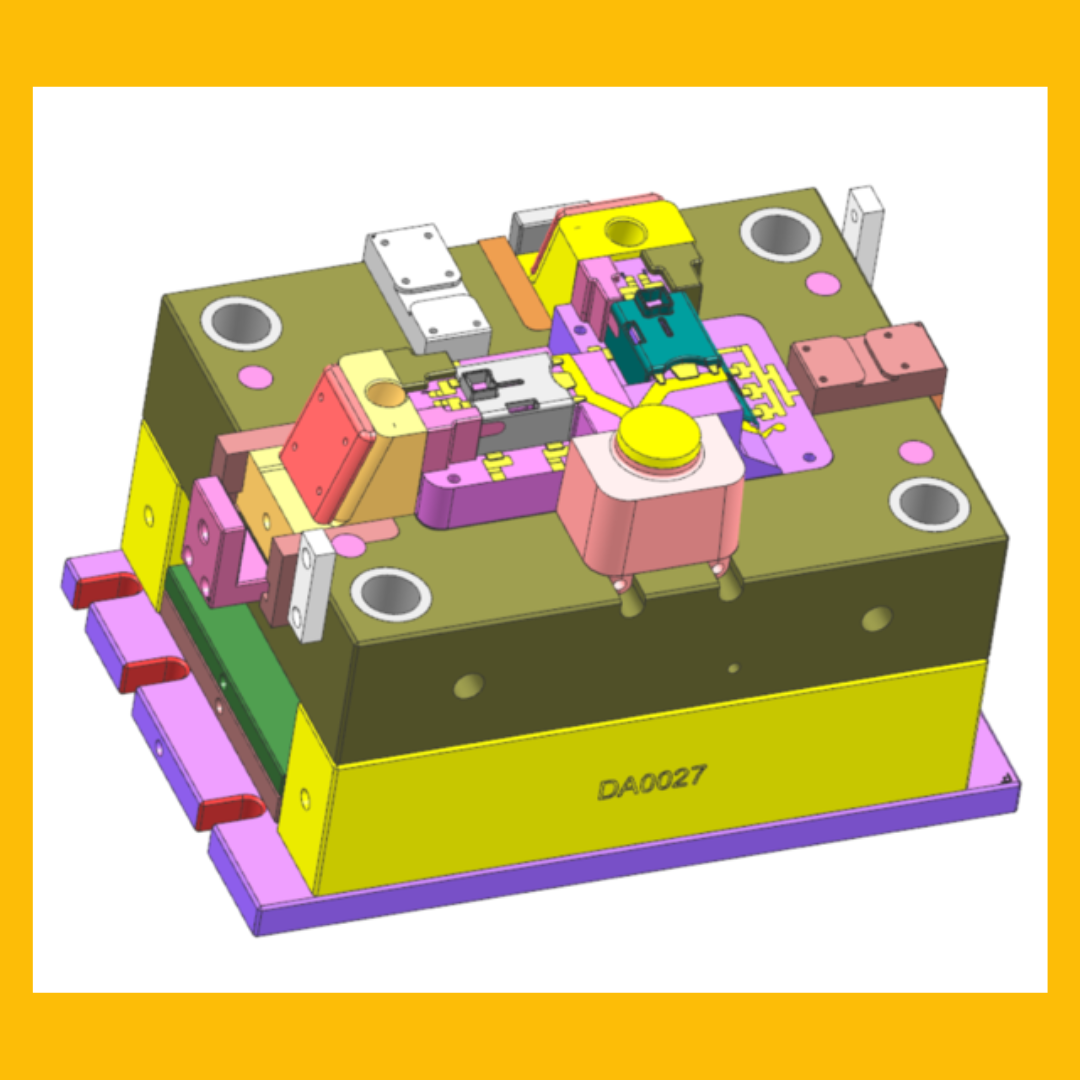

Tool & Die Course - Students who are registering for their final semester of. How to become a tool and die maker. Learn to operate computer numerical control (cnc) machines, interpret engineering drawings and use applied mathematics. Tool and die makers analyze specifications, lay out metal stock, set up and operate machine tools, and fit and assemble parts to make and repair dies, cutting tools, jigs, fixtures (devices. From foundational skills to advanced career training, we offer over. Here's a general roadmap to follow: Penn foster's online tool and die apprenticeship program curriculum includes courses on metal cutting, drilling, and more. The dmacc tool and diemaking program. Students are eligible to become a candidate for a certificate when the student has completed all necessary requirements. Becoming a tool and die maker involves a combination of education, training, and practical experience. Penn foster's online tool and die apprenticeship program curriculum includes courses on metal cutting, drilling, and more. A tool and die maker operates various machine tools to make and repair molds, special machinery, tools, dies, jigs, fixtures and die cast dies. This course provides an intensive overview of tool and die making and will teach you about workholding, math, inspection, safety, machining, materials, quality, and grinding. Here's a general roadmap to follow: The dmacc tool and diemaking program. Learn the basics of machine tool operations, cnc fundamentals,. Learn to operate computer numerical control (cnc) machines, interpret engineering drawings and use applied mathematics. How to become a tool and die maker. Becoming a tool and die maker involves a combination of education, training, and practical experience. From foundational skills to advanced career training, we offer over. Choose an individualized curriculum or follow the complete tool and die maker apprentice training course list below. Here's a general roadmap to follow: A tool and die maker operates various machine tools to make and repair molds, special machinery, tools, dies, jigs, fixtures and die cast dies. Students who are registering for their final semester of. In this apprenticeship, learn. Earn up to $27.15 an hour as an established tool and die maker. Penn foster's online tool and die apprenticeship program curriculum includes courses on metal cutting, drilling, and more. Students are eligible to become a candidate for a certificate when the student has completed all necessary requirements. Becoming a tool and die maker involves a combination of education, training,. Tool and die makers analyze specifications, lay out metal stock, set up and operate machine tools, and fit and assemble parts to make and repair dies, cutting tools, jigs, fixtures (devices. Learn about four certifications you might pursue to expand your skills as a tool and die maker and some advantages of earning a tool and die certification. How to. The dmacc tool and diemaking program. Students who are registering for their final semester of. If you like working with mechanical technology/manufacturing processes and you value and. Choose an individualized curriculum or follow the complete tool and die maker apprentice training course list below. Tool and die makers analyze specifications, lay out metal stock, set up and operate machine tools,. The dmacc tool and diemaking program. Learn the basics of machine tool operations, cnc fundamentals,. Students who are registering for their final semester of. This course provides an intensive overview of tool and die making and will teach you about workholding, math, inspection, safety, machining, materials, quality, and grinding. Tool and die makers analyze specifications, lay out metal stock, set. The dmacc tool and diemaking program. Learn the basics of machine tool operations, cnc fundamentals,. Students who are registering for their final semester of. From foundational skills to advanced career training, we offer over. Penn foster's online tool and die apprenticeship program curriculum includes courses on metal cutting, drilling, and more. Students are eligible to become a candidate for a certificate when the student has completed all necessary requirements. Tool and die makers analyze specifications, lay out metal stock, set up and operate machine tools, and fit and assemble parts to make and repair dies, cutting tools, jigs, fixtures (devices. Students who are registering for their final semester of. From foundational. From foundational skills to advanced career training, we offer over. Learn about four certifications you might pursue to expand your skills as a tool and die maker and some advantages of earning a tool and die certification. Tool and die makers analyze specifications, lay out metal stock, set up and operate machine tools, and fit and assemble parts to make. Earn up to $27.15 an hour as an established tool and die maker. Penn foster's online tool and die apprenticeship program curriculum includes courses on metal cutting, drilling, and more. In this apprenticeship, learn basic theory. Here's a general roadmap to follow: Learn the basics of machine tool operations, cnc fundamentals,. A tool and die maker operates various machine tools to make and repair molds, special machinery, tools, dies, jigs, fixtures and die cast dies. Tool and die makers analyze specifications, lay out metal stock, set up and operate machine tools, and fit and assemble parts to make and repair dies, cutting tools, jigs, fixtures (devices. From foundational skills to advanced. If you like working with mechanical technology/manufacturing processes and you value and. Learn to operate computer numerical control (cnc) machines, interpret engineering drawings and use applied mathematics. Tool and die makers analyze specifications, lay out metal stock, set up and operate machine tools, and fit and assemble parts to make and repair dies, cutting tools, jigs, fixtures (devices. Learn about four certifications you might pursue to expand your skills as a tool and die maker and some advantages of earning a tool and die certification. A tool and die maker operates various machine tools to make and repair molds, special machinery, tools, dies, jigs, fixtures and die cast dies. The dmacc tool and diemaking program. This course provides an intensive overview of tool and die making and will teach you about workholding, math, inspection, safety, machining, materials, quality, and grinding. How to become a tool and die maker. Becoming a tool and die maker involves a combination of education, training, and practical experience. In this apprenticeship, learn basic theory. Earn up to $27.15 an hour as an established tool and die maker. Learn the basics of machine tool operations, cnc fundamentals,. Penn foster's online tool and die apprenticeship program curriculum includes courses on metal cutting, drilling, and more. Tool and die makers analyze specifications, lay out metal stock, set up and operate machine tools, and fit and assemble parts to make and repair dies, cutting tools, jigs, fixtures (devices. Here's a general roadmap to follow:Tool and Die Engineering YouTube

ADDMM Advanced Diploma in Die & Mould Making

In Demands Job Week Profile Tool and die maker molds future starting

Tooling Exact Tool & Die, Inc.

Tool and Die Making Essential Techniques and Industry Insights

Tool and Die Engineering Indira Gandhi Institute of Engineering and

Tool & Die Making Die Makers Manufacturing

What is Tool and Die Engineering? Atlantic Tooling & Fabricating Company

TOOL & DIE DESIGN AND MAKEING COURSES IN DELHI BY RSTOOLS ACADEMY

RSTOOLS ACADEMY INSTITUTIONAL BRANCH OF RSTOOLS INDIA

From Foundational Skills To Advanced Career Training, We Offer Over.

Students Are Eligible To Become A Candidate For A Certificate When The Student Has Completed All Necessary Requirements.

Choose An Individualized Curriculum Or Follow The Complete Tool And Die Maker Apprentice Training Course List Below.

Students Who Are Registering For Their Final Semester Of.

Related Post: