Design For Manufacturing Course

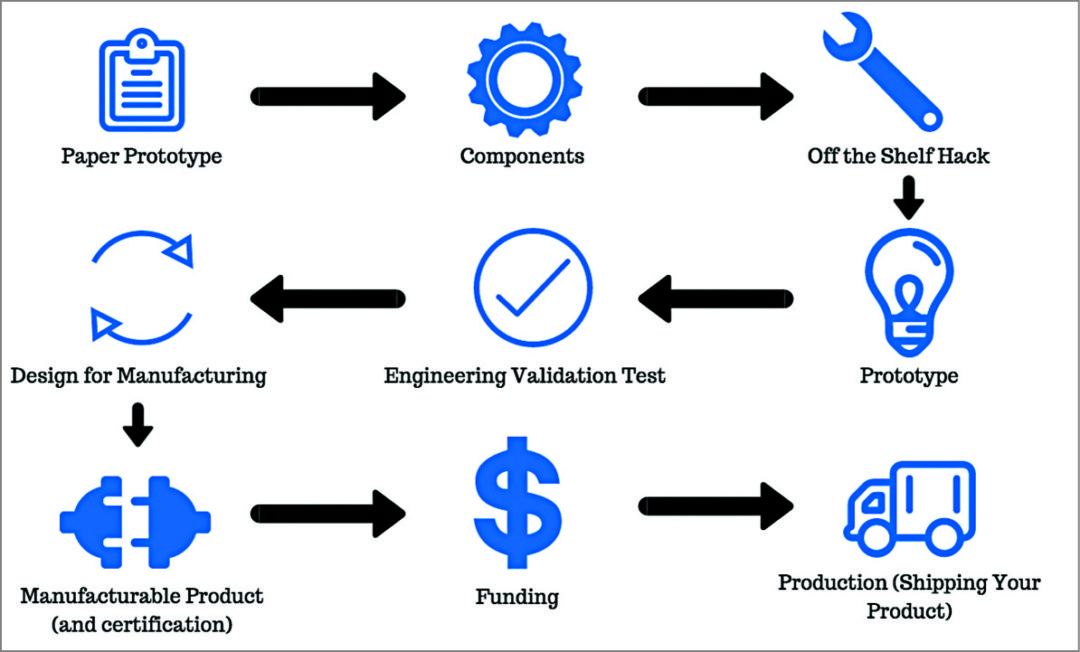

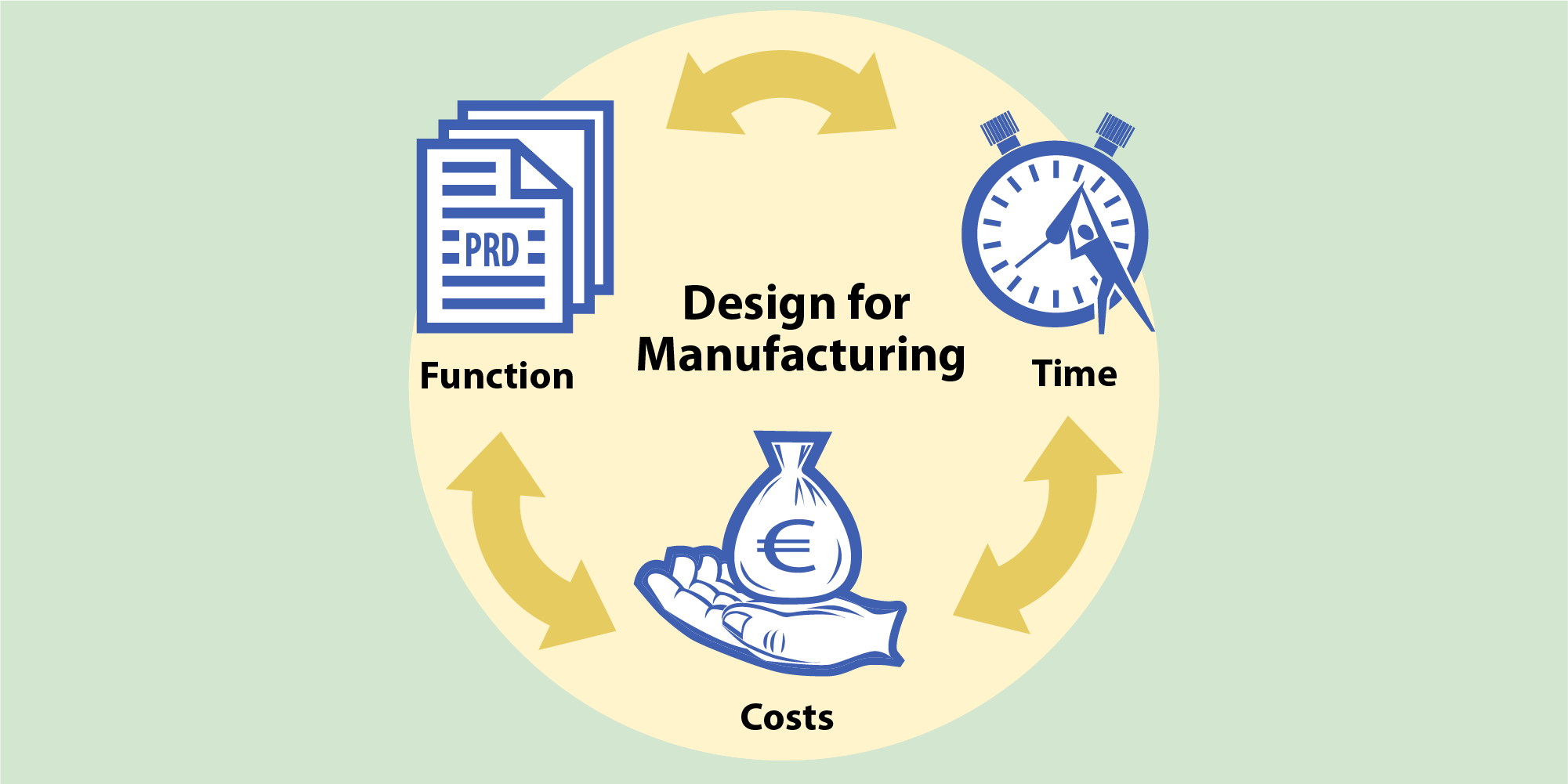

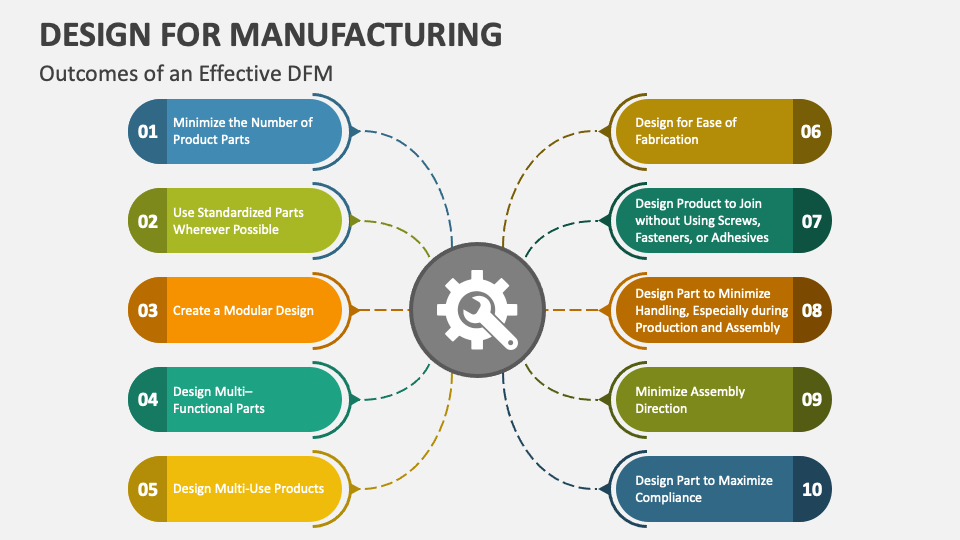

Design For Manufacturing Course - After completing this course, you’ll be able to: Up to 7% cash back learn best practices that’ll keep control of your designs from sketch all the way to production. Design for manufacturing (dfm) is the process of designing parts, components or products for ease of manufacturing to make a better product at a lower cost. Understand how manufacturing philosophy and volume. At its core, dfm involves considering. Up to 10% cash back this course attempts to cover the basics of designing for manufacturing including selecting a suitable process based on various criteria and designing for the process. The dfma methodology allows for new or improved products to be designed, manufactured and offered to the consumer in a shorter amount of time. Improve product quality by integrating manufacturing considerations. Explore how to apply complimentary industry 4.0 tools such as digital twins, smart factories, smart manufacturing, big data and sensors. Explore best practices for reducing assembly complexity. Discussions with manufacturing managers highlighted a strong demand for similar training programmes tailored for professionals, creating new collaboration opportunities. Acquire techniques for optimizing product designs to reduce production costs. Dfm is the classic method of creating good product designs that reduce part count, simplify manufacturing techniques, and standardize parts and materials with the ultimate goal of. Up to 10% cash back this course attempts to cover the basics of designing for manufacturing including selecting a suitable process based on various criteria and designing for the process. Learn how to identify and eliminate potential manufacturing and assembly challenges in the design phase. Design for manufacturing and assembly (dfm+a), pioneered by boothroyd and dewhurst, has been used by many companies around the world to develop creative product designs that use. At its core, dfm involves considering. Read blogget a quoteview servicesclient driven This professional development hour provides professional engineers with a comprehensive understanding of design for manufacturing and assembly (dfma) by exploring its principles,. Learn to apply microsoft design system guidelines and create enterprise software interfaces. Dfm is the classic method of creating good product designs that reduce part count, simplify manufacturing techniques, and standardize parts and materials with the ultimate goal of. Learn to minimize costs through optimized design. Learn techniques to simplify product designs for ease of manufacturing and. Over five days, you will gain. At its core, dfm involves considering. Improve product quality by integrating manufacturing considerations. Over five days, you will gain. Understand the fundamental principles of design for manufacturing (dfm) and design for assembly (dfa). Explore best practices for reducing assembly complexity. Learn how to identify and eliminate potential manufacturing and assembly challenges in the design phase. After completing this course, you’ll be able to: Improve product quality by integrating manufacturing considerations. Learn techniques to simplify product designs for ease of manufacturing and. Design for manufacturing (dfm) is the process of designing parts, components or products for ease of manufacturing to make a better product at a lower cost. Over five days, you will gain. Learn how to identify and eliminate potential manufacturing and assembly challenges in the design phase. The dfma methodology allows for new or improved products to be designed, manufactured and offered to the consumer in a shorter amount of time. After completing this course, you’ll be able to: Learn to minimize costs through optimized design. This course covers ux/ui principles, wireframing,. The dfma methodology allows for new or improved products to be designed, manufactured and offered to the consumer in a shorter amount of time. Discussions with manufacturing managers highlighted a strong demand for similar training programmes tailored for professionals, creating new collaboration opportunities. Explore how to apply complimentary industry 4.0 tools such as digital twins, smart factories, smart manufacturing, big. Design for manufacturing and assembly (dfm+a), pioneered by boothroyd and dewhurst, has been used by many companies around the world to develop creative product designs that use. This course covers ux/ui principles, wireframing, mockups, and product testing. Understand the fundamental principles of design for manufacturing (dfm) and design for assembly (dfa). Learn techniques to simplify product designs for ease of. Dfm is the classic method of creating good product designs that reduce part count, simplify manufacturing techniques, and standardize parts and materials with the ultimate goal of. Up to 7% cash back learn best practices that’ll keep control of your designs from sketch all the way to production. Learn to apply microsoft design system guidelines and create enterprise software interfaces.. Learn to apply microsoft design system guidelines and create enterprise software interfaces. Explore how to apply complimentary industry 4.0 tools such as digital twins, smart factories, smart manufacturing, big data and sensors. Learn techniques to simplify product designs for ease of manufacturing and. Understand how manufacturing philosophy and volume. At its core, dfm involves considering. Explore best practices for reducing assembly complexity. Up to 10% cash back this course attempts to cover the basics of designing for manufacturing including selecting a suitable process based on various criteria and designing for the process. Read blogget a quoteview servicesclient driven Acquire techniques for optimizing product designs to reduce production costs. At its core, dfm involves considering. Learn to minimize costs through optimized design. After completing this course, you’ll be able to: Understand the fundamental principles of design for manufacturing (dfm) and design for assembly (dfa). Learn techniques to simplify product designs for ease of manufacturing and. This professional development hour provides professional engineers with a comprehensive understanding of design for manufacturing and assembly (dfma) by exploring. At its core, dfm involves considering. Learn how to identify and eliminate potential manufacturing and assembly challenges in the design phase. Learn to apply microsoft design system guidelines and create enterprise software interfaces. Up to 7% cash back learn best practices that’ll keep control of your designs from sketch all the way to production. Explore best practices for reducing assembly complexity. This course covers ux/ui principles, wireframing, mockups, and product testing. Over five days, you will gain. Improve product quality by integrating manufacturing considerations. Dfm is the classic method of creating good product designs that reduce part count, simplify manufacturing techniques, and standardize parts and materials with the ultimate goal of. This professional development hour provides professional engineers with a comprehensive understanding of design for manufacturing and assembly (dfma) by exploring its principles,. Design for manufacturing and assembly (dfm+a), pioneered by boothroyd and dewhurst, has been used by many companies around the world to develop creative product designs that use. The dfma methodology allows for new or improved products to be designed, manufactured and offered to the consumer in a shorter amount of time. After completing this course, you’ll be able to: Discussions with manufacturing managers highlighted a strong demand for similar training programmes tailored for professionals, creating new collaboration opportunities. Acquire techniques for optimizing product designs to reduce production costs. Read blogget a quoteview servicesclient drivenDFM Tools Picking Proper Design for Manufacture Tools

The Importance of Design for Manufacturing

Design for manufacturing High Tech Institute design for

Design For Manufacturing Course by DFR PDF Reliability

Design for Manufacturing Course 1 Manufacturing Overview

Lesson 6 Design for Manufacturing.pdf Production And Manufacturing

Design for Manufacturing (DFM) Everything You Need to Know

PPT Principles of Design for Manufacturing PowerPoint Presentation

Design for Manufacturing PowerPoint and Google Slides Template PPT Slides

Design for Manufacturing Course 11 Part 1 Design for Manual Assembly

Design For Manufacturing (Dfm) Is The Process Of Designing Parts, Components Or Products For Ease Of Manufacturing To Make A Better Product At A Lower Cost.

Up To 10% Cash Back This Course Attempts To Cover The Basics Of Designing For Manufacturing Including Selecting A Suitable Process Based On Various Criteria And Designing For The Process.

Understand The Fundamental Principles Of Design For Manufacturing (Dfm) And Design For Assembly (Dfa).

Explore How To Apply Complimentary Industry 4.0 Tools Such As Digital Twins, Smart Factories, Smart Manufacturing, Big Data And Sensors.

Related Post: